As I mentioned earlier, the building we’re putting up is a Sierra style. If the building you ordered is a Teton or a Sonoran, you have no girts or hat channel as your panels are put on horizontally and affixed to the 2 inch x 3 inch vertical framing. In the case of the Mohave, you have hat channel on the roof and no girts.

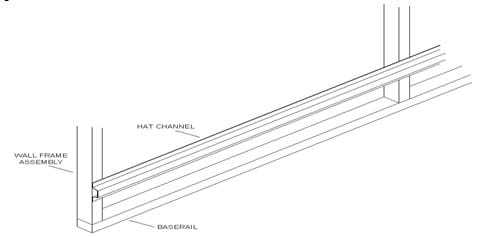

Now let’s get on with the hat channel and girt installation in this Sierra building…

We are going to start with the hat channel. The first thing we need to do is align the hat channel with the vertical pins on the base rails and make reference marks, again a Sharpie pen works well for this.

The guys installing this building use framing screws to temporarily hold the hat channel while they mark it, a c-clamp will accomplish the same thing. We used 15’- 1” and 10’-1” lengths of hat channel for our 25’ long building, check your material list and installation instructions to see what lengths are used on your building. You will want to make the reference marks on at least three rows of hat channel. One for each side of the building at the eave bracket and one for one side of the peak.

Now let’s install the hat channel on the roof. Spacing of the hat channel is different based upon building widths and Snow Loads. Refer to your Assembly Manual and it has a diagram showing what the spacing should be for the building you bought.

Remember back on Step Seven when we marked the intervals that the Hat Channel would be attached on the roof framing? Well, on this building, a 20 foot wide, the intervals we marked on the rafters was every 38 3/8th inches beginning at the very edge of the Eave Bracket. So there’s going to be four rows or courses on each side of this building, running horizontally from front to rear. Install the two rows at the eave bracket first and then the remaining row with reference marks on one side of the peak or the other. Fill in the remaining rows of hat channel; reference marks on the remaining rows are not needed on a building this wide. If your building is wider you may want to make reference marks on a couple more rows of hat channel to place in the middle of the span.

We supply Hat Channel in lengths that are an extra inch or so long per piece. When you order a building, its actual length is actually two inches longer that what it states. For example this 25 foot long building is really 25 feet, 2 inches long. When you reach the end of a piece of Hat Channel, just line it up with the middle of the rafter so you can use the remaining portion of the rafter to affix the other one. At the end you obviously wouldn’t want any hanging over past the end, so just overlap if necessary to make your Hat Channel flush with the ends of your building.

Use vice grips or some type of clamp to hold the Hat Channel to the frame so it doesn’t move while you’re putting in your Frame Screws. Put two Frame Screws into each rafter through each side of the Hat Channel.

The side girts are next.

Girts are made out of 11/2 inch x 11/2 inch tube. They are affixed to the sidewalls using three types of brackets. BK 30 Brackets or Single Brackets are used to attach girts at the ends of the building or at windows or doorways. When you use Single Brackets, use the pan head screws that came with your kit to attach to the outside of the walls. This is because they will be flush with the surface of the exterior walls and won’t distort your panels when you put these on in a few minutes. BK 31 or Double Brackets are used to attach girts to the center sides of 2 inch wide frame members. There may be times, but only on the Back Enclosure and Front Enclosure, where you’ll use 2 of the Single Brackets overlapped to affix the girts. The BK 31W which is a Double Bracket that’s made a bit wider than the normal Double Bracket only goes up on the very top course. It’s made that way because it needs to fit over each of the Eave Brackets.

Consult your Assembly Manual for the spacing to put the Girts on the sidewalls. For this building, they’re going to be installed about 49 ½ inches apart. Start at the top, using the BK31W Brackets and the Single Brackets on each end. BK31w brackets are especially made to fit over the eave brackets and this top row of girts is the only place you’ll use this type of girt bracket. Your girts up on the top row should be 3 inches down from the edge of the eave. Whenever installing girts, a much cleaner job is achieved by measuring and marking the first and last vertical upright and then snapping a chalk line. Later when applying the exterior panels to the outside, this will enable you to have nice straight lines of panel screws. Using clamps to hold parts in place is real handy throughout the installation of girts and purlins.

After installing the top row, use a measuring tape to measure down 49 ½ inches on each end and then use a chalk line to guide your placement on all the other uprights so everything looks real nice—remember, you won’t be happy if you don’t get your girts lined up with a chalk line like I described before.

Step 14: Radiant Barrier Insulation

Video Index:

1. The foundation

2. Eave or corner brackets

3. Roof & wall assembly

4. Truss assembly

5. Hat channel spacing

6. Base rail assembly

7. Anchoring base rails

8. Wall & roof to base

10. Install back enclosure

11. Install front enclosure

12. Door & window frame

13. Girts & hat channel

14. Radiant barrier insulation

15. Side exterior panels

16. Gable end panels

18. Corner trim

19. Roof panels

20. Doors & windows

21. Eave trim

22. Gable trim

23. Ridge cap

24. Finishing touches